The DIGITIMES Research special report you are trying to open is sold a-la-carte and is also available with Semiconductors Special Report Database services. Please sign in if you wish to continue.

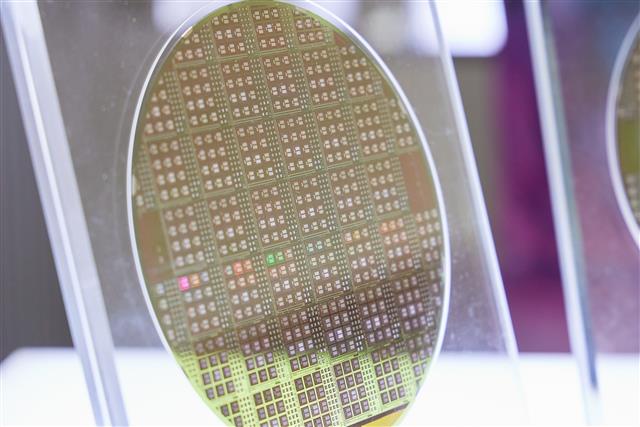

Soaring silicon carbide (SiC) demand from electric vehicles (EV) is leading to a tight supply of 6-inch SiC wafers, of which the cost will unlikely go down.

Abstract

To raise SiC capacity while lowering the cost, leading global IDMs including Wolfspeed, STMicroelectronics (ST) and Rohm undertake plans to volume produce 8-inch SiC wafers sometime between 2022 and 2024.

To meet the enormous SiC demand from EVs, SiC wafer producers are on course to transition toward 8-inch wafer production. In comparison to a 6-inch wafer, 1.8 times more dies can be produced on an 8-inch wafer and the yield loss at the wafer edge is 7pp lower.

Moreover, the production equipment for 8-inch wafers costs not much higher than that for 6-inch wafers so the unit cost for components made from an 8-inch wafer is 17% lower than from a 6-inch wafer.

Table of contents

Price: NT$14,000 (approx. US$500)