Climate change has shaken the world. Taiwan as an island is no exception and has been stricken with rising heat, abnormal weather patterns, and drought. In the last two years, Taiwan has seen such severe droughts that the central government set up a drought emergency response center to take all necessary measures to conserve water.

The emergency response center, when not in times of drought, has begun constructing seawater desalination plants to ensure water supply. However, the costs of commonly-used technologies to desalinate seawater remain prohibitively high. There are also technical issues remaining to be solved. For example, the water can hardly be used by the semiconductor industry for cooling, and processing the minerals in seawater is still a challenge.

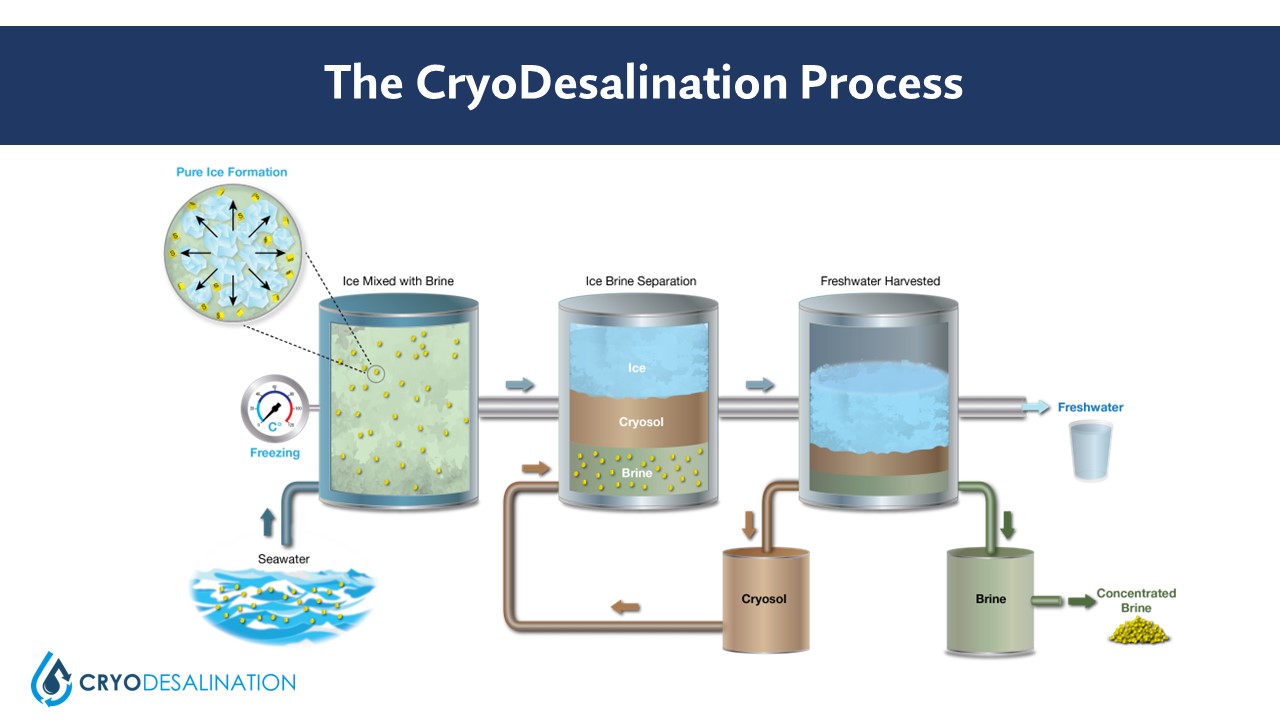

CryoDesalination, a US-based startup specializing in processing seawater in a sustainable way, which has won the first place of this years' TIE Awards for net-zero emission, said it has developed a much simpler and lower cost way to turn seawater into drinking water. CryoDesalination uses a natural phenomenon as the centerpiece of its process: when saltwater freezes, the ice is pure. CryoDesalination's patented process has much lower capital and operating costs than the legacy seawater desalination technologies.

According to public information, the reverse osmosis desalination plant built by Formosa Petrochemical Corporation in Yunlin county, Taiwan required a total investment of NT$6.8 billion (US$210 million) and more than 70 million kWh in energy, emitting around 6,000 tonnes of carbon, to eventually produce 100,000 tonnesof desalinated water per day.

In contrast, according to industry researchers, integrating CryoDesalination's zero carbon solution with the liquefied natural gas (LNG) plants in Taichung and Yung -An would require a fraction of the investment, which is estimated to be NT$787 million (US$24 million), the CryoDesalination plants would not use any electrical power or have any carbon emissions; the estimated daily production of desalinated water could reach 66,000 tonnes.

CryoDesalination: powered by waste energy

These exceptionally low costs are possible because Taiwan's LNG regasification terminals release cold waste energy that CryoDesalination can use as a clean power source to desalinate water. Co-locating LNG terminals with CryoDesalination eliminates power costs for freezing the seawater and significantly simplifies the CryoDesalination Units.

Re-using the waste energy released from the vaporization of liquified natural gas is part of sustainable cycle the company envisions. Company CEO and co-founder William Buchsbaum added that LNG regasification plants are located on the coast where seawater is available to be processed into clean water to satisfy industrial, agricultural, and residential demand.

CryoDesalination will present its zero-carbon solution at the TIE Awards on October 12-14 in Taipei. The company has expressed high interest in connecting with industrial players in Taiwan to process seawater.

CryoDesalination Process